在 Harper,创新就是标准。我们提供给客户的每个一流系统,都是利用我们在热处理方面多年的经验、渊博的专业知识和丰富的工具集以及经证明的许多技术专利打造而成。

下面介绍的只是我们已获专利的少数几项创造性解决方案,它们为市场带来了最精确的工程设计。

垂直输送机 – 哈珀专利的垂直输送机炉是我们最新的产品原料广泛的热加工技术的创新,特别是对于需要高温固 – 固和固 – 气反应,如碳化物,氮化物,硼化物和耐火金属粉末材料。读更多…

理想的回混流 – 用于旋转炉的 Riffle-Flights,通过提供用于以固定平均混合物进行处理(连续或分批次)的轴向混合、慢化放热反应或仅仅只是连续的线上混合,实现吞吐量的增加。

理想的回混流 – 用于旋转炉的 Riffle-Flights,通过提供用于以固定平均混合物进行处理(连续或分批次)的轴向混合、慢化放热反应或仅仅只是连续的线上混合,实现吞吐量的增加。

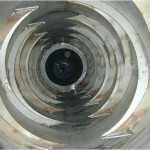

旋转管的优良密封 – 实现最低限度的大气消耗。密封净化率降低 10-100 倍,从而确保了炉气纯度并大大提高了产品纯度。

多流氧化炉 (正在申请专利) – 在单个炉中同时实现平行、交叉和向下方向气流的独特气流分布系统。一致的规范使每个气流体系都能达到甚至超过自身的最佳效果。

专门的净化室 – 设计用于两端开口的槽式炉,这种设计保证了炉内气体环境的纯净,从而有助于保持产品质量。

多轴旋转密封 – 便于进行气密性密封以保证炉气纯度和隔离,从而防止生产因停机和维护而中断,并且有助于确保产品质量。

多轴旋转密封 – 便于进行气密性密封以保证炉气纯度和隔离,从而防止生产因停机和维护而中断,并且有助于确保产品质量。

非传统的碳纤维系统 – 使用独特加热方法和材料传送系统处理非传统碳纤维(如隔热垫和织物)的热力学解决方案。

多区域石墨旋转 – 系统具有多项获得专利的功能,数个温区高达 2400°C,简单、可靠而且可扩展。是高纯度应用环境的理想选择。

适用于旋转炉的增强栓塞流 – 螺旋刮板不经回混而传送材料,对于需要减少停留时间的流程来说至关重要。