Faser-Prozesstechnologie Flexibilität zur Änderung und Modifikation zu bieten. Unser System ist für Maschinengeschwindigkeiten von 0,1 m/min bis über 1 m/min und Spinnkabel von 10 bis 48.000 Einzelfasern ausgelegt.

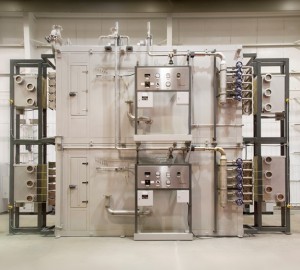

Unsere vollintegrierten, umfangreich ausgestatteten Microline-Anlagen sind für die kundenspezifische Anpassung konfiguriert und zeigen dieselbe hohe Leistung wie unsere Produktionsanlagen, sind jedoch für Kunden in Forschung und Entwicklung dimensioniert. Die meisten Prüfungen im Labormaßstab werden in diskontinuierlichen Batch-Verarbeitungsschritten durchgeführt; das System von Harper International ermöglicht die kontinuierliche Aufarbeitung des Einzelfasermaterials. Das System ist sowohl für potenzielle Industriekunden wie auch für nationale und akademische Forschungsinstitute gleichermaßen geeignet.

Unsere vollintegrierten, umfangreich ausgestatteten Microline-Anlagen sind für die kundenspezifische Anpassung konfiguriert und zeigen dieselbe hohe Leistung wie unsere Produktionsanlagen, sind jedoch für Kunden in Forschung und Entwicklung dimensioniert. Die meisten Prüfungen im Labormaßstab werden in diskontinuierlichen Batch-Verarbeitungsschritten durchgeführt; das System von Harper International ermöglicht die kontinuierliche Aufarbeitung des Einzelfasermaterials. Das System ist sowohl für potenzielle Industriekunden wie auch für nationale und akademische Forschungsinstitute gleichermaßen geeignet.

Harper-Anlagen ermöglichen die optimale Kontrolle kritischer Prozessparameter, darunter die Steuerung der Zugspannung nach Betrieb der einzelnen Einheiten und die Mehrzonen-Temperaturregelung bei der Oxidation, der Vorkarbonisierung und der Karbonisierung. Unsere Antriebssysteme sind im Hinblick auf die präzise Kontrolle der an die Faser übertragenen Kräfte ausgelegt und bieten Flexibilität bezüglich Anzahl der Spinnkabel, Belastung und Antriebsposition. Diese Flexibilität gestattet eine bessere kundenspezifische Anpassung der Oxidation durch Einstellung individueller Zonen, individueller Durchläufe und der Karbonisierung.

Wenn Investitionsüberlegungen oder Fragen zur technischen Konfiguration anstehen, ist zu beachten, dass das System auch mit folgenden Merkmalen ausgelegt werden kann:

- einzelne oder mehrere Tauchanlagen zur Oberflächenbehandlung

- moderne Hochtemperaturöfen (HT-Öfen) für Temperaturen bis zu 1800 °C

- wahlweise Ultrahochtemperaturöfen (UHT-Öfen) zur Untersuchung von Hochmodulfasern für Temperaturen bis zu 2800 °C

- Konfiguration des Steuersystems im Hinblick Ihrer Präferenzen für Fernzugriff und Datenarchivierung.

- Materialtransport für neue Ausgangsmaterialien, darunter solche, die eine Bandförderung erfordern

Darüber hinaus stellt Harper seinen Kunden bei Bedarf Prüfeinrichtungen zur Verfügung, um Scale-up und Prozessentwicklung zu unterstützen, bevor Anlageinvestitionen getätigt werden.

Anlagenbetrieb

Unser Microline-System umfasst folgende vielseitig konfigurierbare Betriebsschritte:

Unser Microline-System umfasst folgende vielseitig konfigurierbare Betriebsschritte:

- Spulengestell: Bis zu acht (8) Positionen

- Oxidationsofen: Bis zu Temperaturen von 300 °C, mit Mehrzonenregelung

- Antriebsgestelle: Mehrere Positionen über die Anlage verteilt

- Niedriger Mindestlastangriffspunkt, um Untersuchungen an Fasern mit kleinsten Filamentzahlen zu ermöglichen

- Niedrig- und Hochtemperaturofen (LT & HT-Ofen) Vorkarbonisierung und Karbonisierung: Für Temperaturen bis 1000 °C bzw. 1600 °C, mit Mehrzonenregelung, atmosphärisch geregelt

- Optionales Vorbehandlungssystem

- Optionales Oberflächenbehandlungssystem

- Optionales Klassierungssystem

- Optionaler Ultrahochtemperaturofen (HT-Ofen) zur Karbonisierung: Für Temperaturen bis 2800 °C, atmosphärisch geregelt

- Platzbedarf der Gesamtanlage ca. 40 m Länge x 10 m Breite x 4 m Höhe

Anlaufen / Herunterfahren

Das Anlaufen von Harper-Anlagen nimmt ab Umgebungsbedingungen ca. 8 bis 12 Stunden in Anspruch. Das Herunterfahren der Anlage lässt sich in einem kürzeren Zeitrahmen durchführen. Zur Verlängerung der Gerätelebensdauer und zur Reduzierung der thermischen Wechselbeanspruchung empfehlen wir, die LT- und HT-Öfen bei kurzen Stillstandzeiten (z. B. über das Wochenende) auf Temperatur im Leerlauf zu betreiben. Dadurch lässt sich auch der Stromverbrauch optimieren, wenn der Energiebedarf zum Wiederaufheizen der Öfen berücksichtigt wird.

Instandhaltung und Support

Wie immer bietet Harper Optionen für Schulung, Service und Instandhaltung, die auf die Bedürfnisse des Kunden zugeschnitten sind. Im Anschluss an die Schulung steht Harper bereit, den reibungslosen Betrieb der Kundenanlage durch laufende und ggf. sofortige Maßnahmen zu unterstützen und sich ändernde Systemanforderungen zu erfüllen – Aktivitäten, für die sich Harper branchenweit einen guten Ruf erworben hat.

Weitere Informationen

- Zugriff auf unsere Expertise – Harpers Archiv mit mehreren Präsentationen speziell über Produktion im Labormaßstab

- Kundenunterstützung zum Scale-up – Harpers Ignite™-Programm

- „Follow the Green“ – Harpers wegweisendes Beacon™-Energiesparprogramm

- Fangen Sie noch heute an – Setzen Sie sich mit Harper in Verbindung, um nähere Informationen zu erhalten