Esta página está en inglés sólo esta vez.

Esta página está en inglés sólo esta vez.

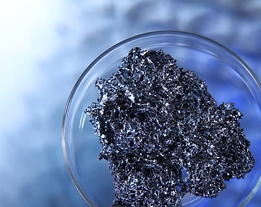

Harper has extensive experience in processing a variety of materials for the Rare Earths market. As Rare Earth materials become increasingly critical to the global supply chain of many new and emerging technologies, manufacturers must rely on a trusted partner like Harper to help scale up and refine their thermal processing regimes. Our solutions have been successful in meeting the exacting demands of this industry while enabling the customer towards greater competitive advantage.

Our customized rotary and pusher systems for Rare Earth processing focus on indirect firing methods, a superior approach to meet the specific demands for this market due to delivering increased product purity and decreased energy consumption. Process materials come in contact only with controlled gases and a pure metal / ceramic tube. Additionally, the temperature profile of an indirect fired furnace can be more accurately controlled. This yields improvement of product quality, grain size distribution (low micron sized range) and morphology of particles. Dust and particle entrainment of the bed material is also substantially reduced in an indirect fired kiln.

Learn more…

- Technology for Rare Earth Processing – Rotary Tube Furnaces

- Technology for Rare Earth Processing – Pusher Tunnel Furnaces

- Scaling up your Production Process – Harper’s Research Center