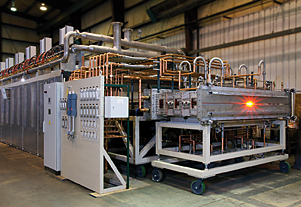

Harper is the industry standard choice in continuous furnace technologies for the Carbon Fiber industry. Our involvement in Carbon Fiber began at the market’s inception in the 1970s, and since then we have been helping fiber manufacturers achieve new and ever greater heights with our continual evolution of design innovations, such as our groundbreaking energy efficiency Beacon program.

Harper is the industry standard choice in continuous furnace technologies for the Carbon Fiber industry. Our involvement in Carbon Fiber began at the market’s inception in the 1970s, and since then we have been helping fiber manufacturers achieve new and ever greater heights with our continual evolution of design innovations, such as our groundbreaking energy efficiency Beacon program.

Harper tailors each design to the customer’s requirements, considering the best possible solution for your needs in terms of element and muffle design, materials platform, and atmospheric considerations to avoid plasma generation for the desired line rates and tow sizes. Our experiences spans a variety of precursors including PAN, pitch, lignin, polyethylene, and rayon in tow, nonwoven mat, or discontinuous, loose fiber form. We also have the unique capability to offer true complete solutions with thoughtful gas treatment and handling systems and integrated control systems. Additionally, Harper is one of few in the market who push the boundaries of technology in offering Ultra High Temperature (UHT) furnace rated to 3000°C.

Harper Slot Furnace Design Enhancements

- Unique end seal design delivers excellent process gas flow uniformity

- Strategic heating element placement to achieve optimal temperature uniformity

- Advanced insulation designs reducing energy consumption

- Inboard and outboard louvers used to minimize ingress of air

- Proven atmosphere purge chambers designs

Harper Slot Furnace Capabilities

- Unique atmospheres (argon, nitrogen, CO2, steam)

- Vertical or Horizontal configurations

- Multiple independently controlled temperature zones (length and width)

- Highly uniform temperature across the towband

- Designed to facilitate service and maintenance activities

- Modular designs minimizing field installation effort

Harper offers specific LT, HT and unique UHT furnace designs for the production of Carbon Fibers:

Harper LT Furnaces

- Electric or Fuel Fired

- Temperature to 1200°C

- Ceramic fiber based insulation

- Nitrogen preheating

- Vent heat tracing

- Microlines™ to large capacities (up to 4 meters; heated lengths to 15 meters)

Harper HT & UHT Furnaces

- Electric Fired

- Temperature to 3000°C

- Materials platform – graphite based

- Microlines™ to large capacities (widths up to 4 meters; heated lengths to 15 meters)

Make Carbon Fiber Greener – Harper’s unique Beacon Program

More than just furnaces – Read about Complete Carbon Fiber Line Solutions

Innovation in action – Our Many Patents for Slot Furnace Designs

Trusted by manufacturers worldwide – Read about recent carbon fiber system installations

Learn from the Leaders – Access our Technical Presentations library